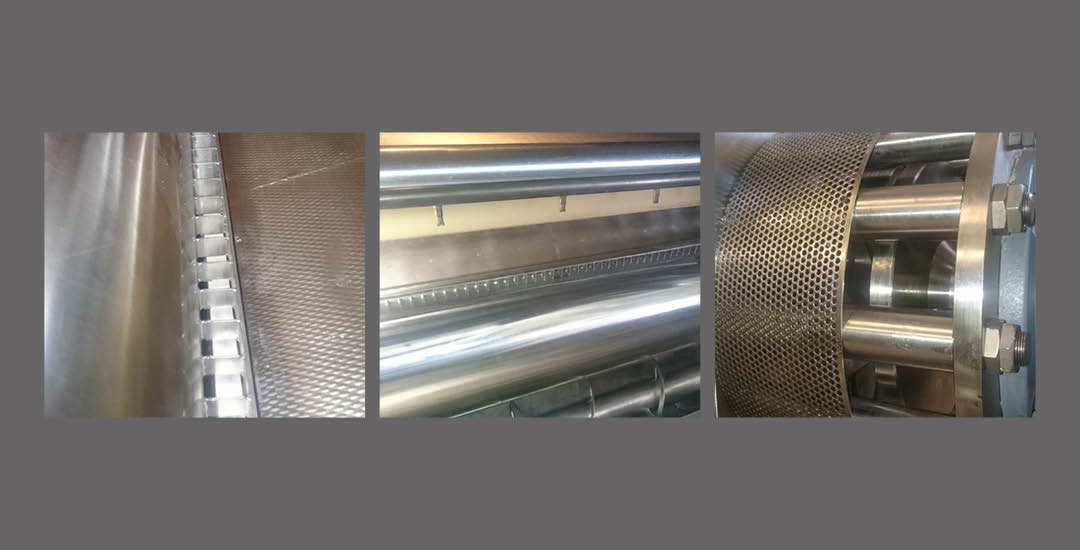

Mechanical design and production equipment

Development and optimization of machinery and production equipment

At Kirkholm, we work on all types of tasks within mechanical design and production equipment. We design, develop, and build new specialized machines that can replace manual processes. We also offer to optimize existing production lines, either through updating and modernizing existing production equipment or through the use of newly developed machines. Kirkholm is with you every step of the way - from idea to a fully operational machine with CE marking, ensuring that everything complies with applicable legal requirements.

At Kirkholm, our primary goal is to create value for our customers. Therefore, we always find a solution that is uniquely tailored to your production, regardless of size and complexity. We have already worked with machine construction and production equipment in various industries.

Hence, we can also assist your company in achieving its goals, whether it's energy optimization, capacity expansion, reduction of workforce needs, minimization of waste, or something entirely different.

How can we assist your company?

We offer advisory services when collaboration objectives are unclear, providing insights into potential outcomes. We fully engage with clients, aligning expectations throughout the collaboration. We specialize in constructing both simple and complex machines, pushing boundaries to meet specific desires. It is important to us to emphasize the correlation between machine complexity and development time, emphasizing ongoing dialogue and expectation alignment.

- Emphasis on understanding diverse customer needs.

- Importance of dialogue and thorough preparation.

- Establishment of collaboration framework and goal discussion.

- Advisory role when collaboration objectives are unclear.

- Full engagement with clients for tailored outcomes.

- Expertise in building simple and complex machines.

- Recognition of correlation between complexity and development time.

- Continuous emphasis on ongoing dialogue and expectation alignment.

Our approach to mechanical design and production equipment

Our mechanical engineers and project managers have many years of experience and has a focus on profitability, quality, and efficiency in all projects.

Our work within machine construction and production equipment is based on the utilization of known technology in innovative ways. We never approach two tasks in the same manner, but draw on previous experience, expertise and knowledge, where we devise new ways to tackle the issue at hand. In this way, we constantly challenge our expertise and creativity to meet the customer's desires.

For refernce you can read about our collaboration with Toms Group on one of their filling lines.

For large and long-term projects, we always break down the process into smaller parts. Even though we have set the direction for the project during the initial meeting, ongoing evaluation is often necessary, allowing for continuous milestones and subtasks. Along the way, we ensure to keep the customer informed about the progress.

Concept development, VR and assembley

In the concept development phase, we utilize Virtual Reality, allowing users to experience and work with the unit in VR. Subsequently, they can provide potential modification suggestions before the machine goes into production. Learn more about Kirkholms use of Virtual Reality here.

When the machinery or production equipment is fully assembled, we will gather feedback from the individuals who use the machine on a daily basis, during the commissioning phase.

We engage in close dialogue and continuously adjust the machine according to their needs.

Additionally, we create user-friendly manuals and guides for the machines, enabling customers to operate them independently and ensuring that the delivery complies with regulations.

OUR

Skills

Concept Development and Ideation

Mechanical development

Automation systems

Guidance and Specifications for

Materials, Surfaces, and Components

Design for manufacturing

Documentation and CE marking

Development of new process systems

Redesign of existing process plants

Optimization and redesign of subcomponents

Mechanical engineering for profitability

When you choose Kirkholm as developer and supplier of your new machines and production equipment, you also choose the value of flexibility. We can help with both short-term tasks that only last a few days and long-term projects that run over several years. We offer special development of machines, but can also act as a technical advisor if you need guidance on which machine to invest in.

In short - our competencies can be used for exactly what your company needs. The goal of the collaboration is that you achieve a positive return on investment through an optimized production.

Contact us to get acquainted and explore what Kirkholm can do for you regarding machine construction and production equipment:

A FEW OF OUR CASES WITHIN MACHINE CONSTRUCTION AND PRODUCTION EQUIPMENT

TERMA | Concept, design and CFD

Go to caseCabinplant | Process equipment for the food industry

Go to caseToms | Optimization of production equipment

Cheese Production | Development & optimization

DO YOU NEED HELP?

We can help you with practical information and answer your questions - give us a call or write to us.

SKANDERBORG

Kirkholm Maskiningeniører A / S

Godthåbsvej 33

8660 Skanderborg

Denmark

FREDERICIA

Kirkholm Maskiningeniører A / S

Bødkervej 7b, 1. tv.

7000 Fredericia

Denmark

HØRSHOLM

Kirkholm Maskiningeniører A / S

Venlighedsvej 6

2970 Hørsholm

Denmark

All Rights Reserved | Kirkholm